Evaporation Plants

Elevate your industrial operations with our Evaporation Plants. Engineered for optimal performance, our plants...

Multi Effect Evaporators

Multiple Effect Evaporators are high-performance HVAC units streamlining liquid concentration.

Wastewater Evaporators

Upgrade your industrial operations with our premium-grade Wastewater Evaporators. Designed for peak efficiency...

Agitated Thin Film Dryer

Film Dryers are industrial machines designed to efficiently remove moisture from thin layers of materials...

Categories

- Evaporation Plants

- Multi Effect Evaporators

- Wastewater Evaporators

- Agitated Thin Film Dryer

- Zero Liquid Discharge System

- Forced Circulation Evaporator

- Membrane Bioreactor

- Industrial Evaporators

- Zero Liquid Discharge Plant

- Wastewater treatment plant

- Effluent treatment plant

- Evaporator

- Vacuum Evaporator

- RO reject evaporator

- Effluent treatment plant manufacturer

- Vertical thin film dryer

- ATFD

- Heat Exchanger

- Multi Effect Evaporation Plant

- Multi Effect Evaporation System

Know More About Us

Agitated Thin Film Dryer

Film Dryers are industrial machines designed to efficiently remove moisture from thin layers of materials...

Our Team

It is the back of our team members that have enabled us to stand out in the market and gather a wide customers base. Based on qualification, experience, skills and knowledge, we have allocated...

Why Us?

We guarantee premium quality of our products as we manufacturer them using the best raw material and latest production technology. We practice fair set of policies that are framed keeping in mind...

About Us

Avail value for money products such as Forced Circulation Evaporation Plant, Wastewater Multi Effect Evaporators, Mechanical Vapor Recompression Mvr, etc..

Vikrama Innovative Technologies is dedicated to achieving the utmost satisfaction of our esteemed customers, recognizing that customer satisfaction is paramount for survival in the competitive market landscape. Through our unwavering commitment to quality and excellence, we have effectively positioned ourselves as a reputable manufacturer and supplier of cutting-edge products like Wastewater Evaporators, Film Dryer, Liquid Discharge System, Membrane Bioreactor, etc. Integrity is the cornerstone of our business philosophy.

MostPopularProducts

Zero Liquid discharge plant

Product Details:

Zero Liquid discharge plant Price And Quantity

- 1000000.00 - 5000000.00 INR/Plant

- 1 Plant

- 10000000 INR/Plant

Zero Liquid discharge plant Trade Information

- Cash in Advance (CID)

- 10 Plant Per Month

- 05 Days

- All India

Product Description

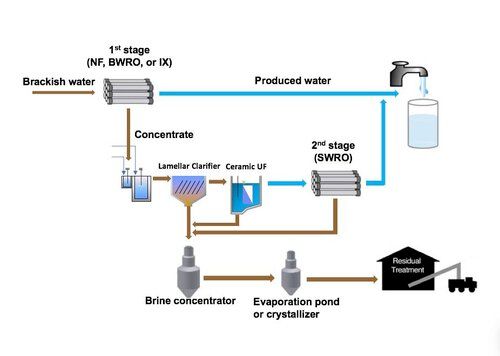

Zero liquid discharge (ZLD) is an engineering approach to water treatment where all water is recovered and contaminants are reduced to solid waste.

While many water treatment processes attempt to maximize the recovery of freshwater and minimize waste, ZLD is the most demanding target because the cost and challenges of recovery increase as the wastewater gets more concentrated. Salinity, scaling compounds, and organics all increase in concentration, which add costs associated with managing these increases. ZLD is achieved by stringing together water treatment technology that can treat wastewater as the contaminants are concentrated.

Targeting ZLD for an industrial process or facility provides a number of benefits:

- Lower waste volumes decrease the cost associated with waste management.

- Recycling water on-site lowers water acquisition costs and risk. Recycling on-site can also result in fewer treatment needs, versus treating to meet stringent environmental discharge standards.

- Reduce trucks associated with off-site wastewater disposal and their associated greenhouse gas impact and community road incident risk.

- Improve environmental performance and regulatory risk profile for future permitting.

- Some processes may recover valuable resources, for example, ammonium sulfate fertilizer or sodium chloride salt for ice melting.

Several methods of waste management are classified as ZLD, despite using different boundaries to define the point where discharge occurs. Usually, a facility or site property line that houses the industrial process is considered the border or 'boundary condition where wastewater must be treated, recycled, and converted to solids for disposal to achieve zero liquid discharge.

Certain facilities send their liquid waste off-site for treatment, deep well disposal, or incineration and they consider this to qualify as ZLD. This approach eliminates the continuous discharge of liquids to surface waters or sewers, but can significantly increase cost.

Why is Zero Liquid Discharge Important?

In a world where freshwater is an increasingly valuable resource, industrial processes threaten its availability on two fronts, unless the water is treated. Many industrial processes require water, and then reduce the availability of water for the environment or other processes, or alternately contaminate and release water that damages the local environment.

Although the history of tighter regulations on wastewater discharge can be traced back to the US Governments Clean Water Act of 1972, India and China have been leading the drive for ZLD regulations in the last decade. Due to the heavy contamination of numerous important rivers by industrial wastewater, both countries have created regulations that require ZLD. They identified that the best means to ensure safe water supplies for the future is to protect rivers and lakes from pollution.

In Europe and North America, the drive towards ZLD has been pushed by high costs of wastewater disposal at inland facilities. These costs are driven both by regulations that limit disposal options and factors that influence the costs of disposal technologies. Tong and Elimelech suggested that, "as the severe consequences of water pollution are increasingly recognized and attract more public attention, stricter environmental regulations on wastewater discharge are expected, which will push more high-polluting industries toward ZLD.

Another important reason to consider ZLD is the potential for recovering resources that are present in wastewater. Some organizations target ZLD for their waste because they can sell the solids that are produced or reuse them as a part of their industrial process. For example, lithium has been found in oil field brines in the USA at almost the same level as in South American scalars. In another example, gypsum can be recovered from mine water and flue gas desalinization (FGD) wastewater, which can then be sold to use in drywall manufacturing.

Regardless of an organizations motivations to target ZLD, achieving it demonstrates good economics, corporate responsibility and environmental stewardship. By operating an in-house ZLD plant, disposal costs can be reduced, more water is re-used, and fewer greenhouse gases are produced by off-site trucking, which minimizes impact on local ecosystems and the climate.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Zero Liquid Discharge System' category

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese