ంభం. మా వినియోగదారుల నమ్మకానికి ఎప్పుడూ ద్రోహం చేయకూడదనే మా నిబద్ధతను మేము నిలకడగా సమర్థించాము, మా వ్యవహారాలన్నింటిలోనూ పారదర్శకత మరియు నిజాయితీని నిర్ధారిస్తాము. అదనంగా, నాణ్యతకు ఎల్లప్పుడూ పరిమాణంపై ప్రాధాన్యత ఇవ్వబడుతుంది, అసాధారణమైన ప్రమాణాలు మరియు కస్టమర్ సంతృప్తికి హామీ ఇవ్వడానికి ఉత్పత్తి ప్రక్రియ యొక్క ప్రతి దశలో కఠినమైన నాణ్యత నియంత్రణ చర్యలు అమలు చేయబడతాయి.

మా బృందం

ఇది మార్కెట్లో నిలబడటానికి మరియు విస్తృత కస్టమర్ల స్థావరాన్ని సేకరించడానికి వీలు కల్పించిన మా జట్టు సభ్యుల వెనుక భాగం. అర్హత, అనుభవం, నైపుణ్యాలు మరియు జ్ఞానం ఆధారంగా, మేము మా జట్టు సభ్యులకు ఒక జట్టు మరియు నిర్దిష్ట హోదాను కేటాయించాము. మేము పరిపూర్ణతతో ప్రతి పనికి మమ్మల్ని ఎనేబుల్ మరియు కస్టమర్ల అంచనాలను మించిపోయే మా జట్టు సభ్యుల గురించి గర్వపడుతున్నాము. మేము మా ఉద్యోగులకు అవసరమైన శిక్షణా కార్యక్రమాలను కూడా అందిస్తాము, తద్వారా వారి నైపుణ్యాలను మెరుగుపరచవచ్చు మరియు వారు సంబంధిత డొమైన్లో ముందుకు ఉండగలరు.

మాకు ఎందుకు?

- మేము ఉత్తమ ముడి పదార్థం మరియు తాజా ఉత్పత్తి సాంకేతిక ఉపయోగించి వాటిని తయారీదారు మా ఉత్పత్తుల ప్రీమియం నాణ్యత హామీ.

- కొనుగోలుదారు యొక్క అంచనాలను మరియు వ్యాపార మా స్వభావాన్ని దృష్టిలో ఉంచుకుని రూపొందించబడిన సరసమైన విధానాలను మేము అభ్యసిస్తాము.

- మేము ఫిల్మ్ డ్రైయర్, మురుగునీటి ఆవిరైటర్లు, మెంబ్రేన్ బయోరియాక్టర్, లిక్విడ్ డిశ్చార్జ్ సిస్టమ్, లిక్విడ్ డిశ్చార్జ్ సిస్టమ్ మొదలైన వాటితో సహా మా ఉత్పత్తులకు సరసమైన ధరను వసూలు చేస్తాము, తద్వారా వినియోగదారులు ఆర్థికంగా దోపిడీకి గురవుతున్నారని

కేటగిరీలు

- బాష్పీభవన మొక్కలు

- మల్టిపుల్ ఎఫెక్ట్ ఆవిరిపోరేటర్లు

- మురుగునీటి ఆవిరిపోరేటర్లు

- కదిలిన సన్నని ఫిల్మ్ డ్రైయర్

- సున్నా ద్రవ ఉత్సర్గ వ్యవస్థ

- ఫోర్స్డ్ సర్క్యులేషన్ ఆవిరిపోరేటర్

- మెంబ్రేన్ బయోఇయాక్టర్

- పారిశ్రామిక ఆవిరిపోరేటర్లు

- Wastewater Treatment Plants

- Wastewater Treatment Plants

- Wastewater Treatment Plants

- Industrial Evaporators

- Industrial Evaporators

- Industrial Evaporators

- Wastewater Treatment Plants

- Industrial Dryers

- Industrial Dryers

- Industrial Evaporators

- Industrial Evaporators

- Industrial Evaporators

About Us

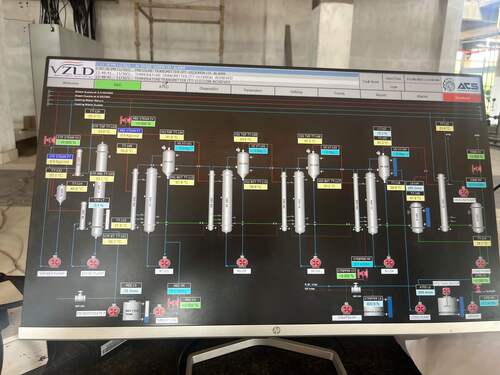

Multi Effect Evaporation plant for Agrow Chemical Industries

వస్తువు యొక్క వివరాలు:

- ఉత్పత్తి రకం Heat Exchanger

- వాడుక Industrial

- వారంటీ 18 month

- మరింత వీక్షించడానికి క్లిక్ చేయండి

ధర మరియు పరిమాణం

- 1

ఉత్పత్తి లక్షణాలు

- Industrial

- Heat Exchanger

- 18 month

వాణిజ్య సమాచారం

- నెలకు

- డేస్

- No

ఉత్పత్తి వివరణ

Multiple Effect Evaporator (MEE)is a system consists of a sequence of heat exchangers. vapor liquid separators used widely for many applications in industries to achieve evaporation and obtain desired concentration as output by using an efficient amount of heat source such as steam or hot water to evaporate water. Evaporation is normally stopped before the solute starts to precipitate in the operation of an evaporator. Most of the industrial evaporators have tubular heating surfaces. The tubes may be horizontal or vertical, long or short and the liquid may be inside or outside the tubes.

A typical feeding method of multi-effect evaporators is forward feed, where both feed and steam are introduced in the first effect and the feed passed from effect to effect parallel to the vapor from the earlier effect. Feeding the steam results in the formation of a small amount of water vapor, which is used to heat the second effect. The vapor releases its latent heat and condense. The released latent heat would result in the formation of a smaller amount of vapor in the second effect. This process is repeated in subsequent effects, until the vapor temperature becomes close to the feed sea water temperature.

The forward configuration requires a pump for feeding of the dilute feed to the first effect. Since a vacuum usually maintained on the last effect, the liquid from one effect to the next effect could be transferred without a pump as the flow occurs in the direction of decreasing pressure. However, a pump is required to remove the concentrated product from the last effect. Forward feeding operation is helpful when the thick liquor or concentrated product may degenerate if exposed to high temperature.

Another feeding method in the multi-effect evaporators is called backward feed configuration. In this type of MEE, heating steam is fed to the first effect whereas feed enters at the last effect, i.e., the coldest effect and is pumped through the successive effects. The backward feeding requires a pump between each pair of effects to transfer liquid from lower pressure effects to higher pressure effects. Backward feed is commonly used when products are viscous and exposure to higher temperature increases the rate of heat transfer due to reduction in viscosity of the liquid.

|

Explanation |

|

|---|---|

|

How it works |

Water is boiled in a series of vessels, each at a lower pressure than the last. The vapor from the previous effect drives the evaporation process. |

|

Benefits |

MEEs are energy efficient, reducing energy consumption by using heat from steam in multiple evaporator bodies. |

|

Types |

Systems with one effect are called single effect evaporators, while those with two successive effects are called double-effect evaporators. Triple effect evaporators have three successive effects. |

|

Applications |

MEEs are used in many industries, including the food and beverage industry, the chemical, pharmaceutical, cosmetic, and perfumery industries, and the paper, minerals, and extraction industries. |

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

Multi Effect Evaporation System లో ఇతర ఉత్పత్తులు

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese